|

Anping County Jinhao Wire Mesh Company Limited.

|

Sack Gabion Gabion Box

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

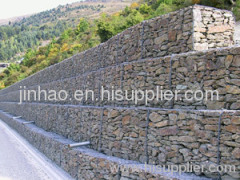

Sack gabions, also called gabion sacks or gabion bags, which are made of 8×10 double twisted steel woven wire mesh, are cylindrical baskets.

Sack gabions, also called gabion sacks or gabion bags, which are made of 8×10 double twisted steel woven wire mesh, are cylindrical baskets. They are filled with stones at the construction sites, and have good flexibility and permeability. The material is steel wire that is heavily galvanized low carbon steel. In addition, all the mesh panel edges are selvedged with wire of a greater diameter to reinforce the structure. In order to meet different customers' requirements, the galvanized gabion sack'dimensions and sizes can be customized.

Packing Terms: basically, all gabion bags are supplied in the form of bundles, which are compressed and strapped together at the factory for easy shipping and handling. Lacing wire is supplied in coils. Ring fasteners are shipped in boxes which must be stored in dry conditions.

Packing Terms: basically, all gabion bags are supplied in the form of bundles, which are compressed and strapped together at the factory for easy shipping and handling. Lacing wire is supplied in coils. Ring fasteners are shipped in boxes which must be stored in dry conditions.

Advantages:

1. It can withstand large-scale deformation and does not collapse.

2. It has a strong resistance to natural destruction and poor weather.

3. Good permeability, which can prevent the damage caused by fluid static.

4. It is convenient to transport as it can be transported folded, assembly on site.

5. Economic and useful: what we need to do is just put the stones into the cage without special skills.

6. Some plants can grow in the gap among the rocks and it can melt with the natural environment surrounding together.

Applications:

They can be extensively used in highway, railway, hillside afforestation, building and breeding, flood fighting net cage, revetment fence, controlling and guiding the direction of river, spillway and diversion channel, rock fall protection, prevention of water loss and soil erosion, embankment protection, protection of the bridge, retaining wall and so on.

Installation and Filling:

Rocks for sack gabions can be produced by any proper quarrying method. They should be of high hardness, whether they are angular or round. What's more, high quality rocks, which shall range between 100mm and 200mm, should be able to withstand current scour as well as weathering. Generally speaking, the range in sizes may allow for a variation of 5% oversize or 5% undersize rock. On any account, the oversize rock shall not be larger than 250 mm, and the undersize rock shall not be smaller than 80 mm. When the gabion sack has been filled properly, the ends of the top spiral wire are pulled tight, twisted and looped onto itself. In order to minimize voids and at the same time achieve a maximum density of the rock in the gabion bags, manual handling is quite necessary.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!